Learning Hub

Featured Courses

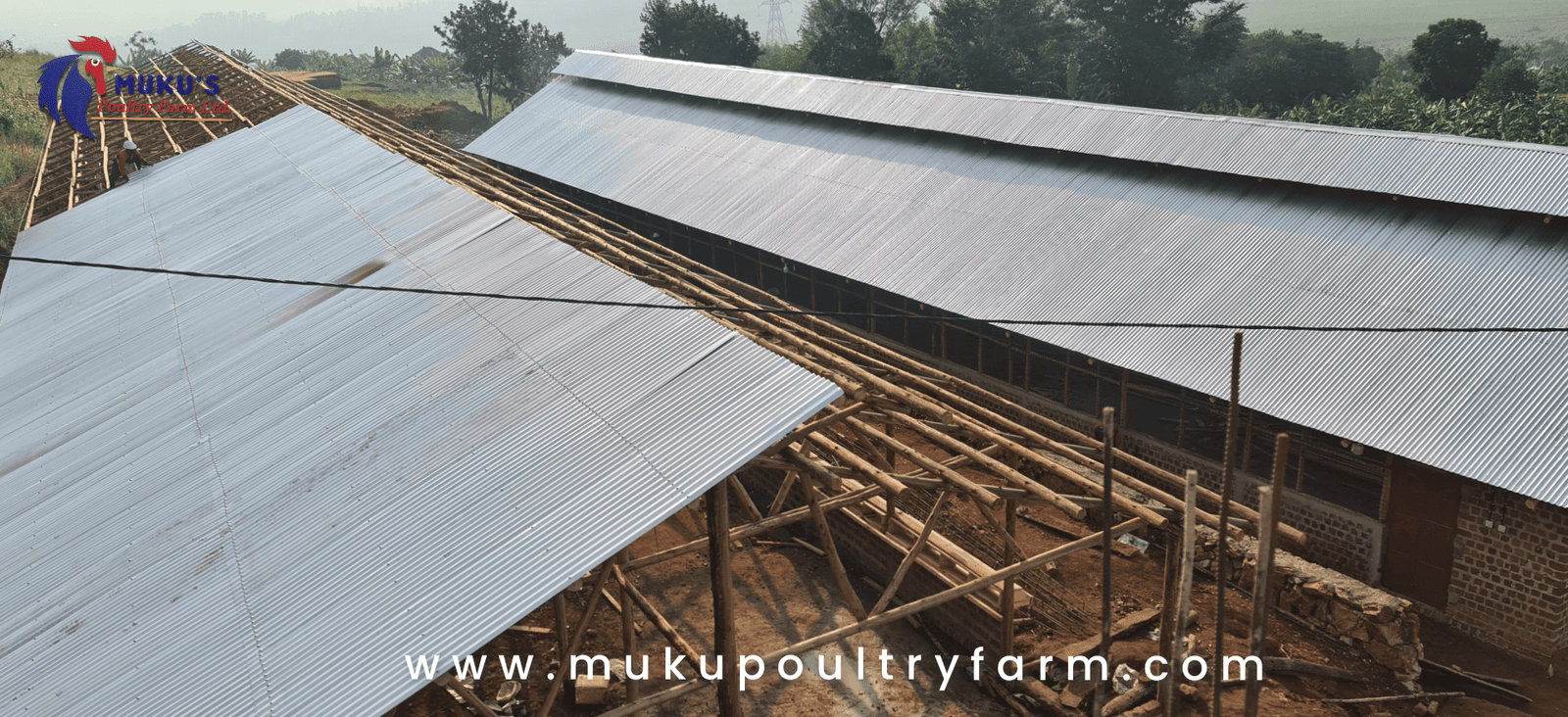

The Ultimate Guide to Poultry Structures

Learn how to plan, design, and build poultry houses suitable for layers, broilers, and indigenous birds. Covers structure types, materials, and deep litter vs cage systems.

8 Core Secrets for Successful Poultry Farming

Discover the foundation principles for lasting success in poultry farming. From passion and research to professional guidance and basic farm knowledge.

THE ULTIMATE GUIDE TO POULTRY STRUCTURES

By Muku's Poultry Farm Ltd – "Starting with us, succeeding with us."

Introduction

Before starting any poultry project, one of the most important steps is understanding the right type of structure for your birds. A well-designed poultry house determines how comfortable, healthy, and productive your birds will be.

This guide explains, in simple and practical terms, how to plan, design, and build poultry houses suitable for layers, broilers, and indigenous birds. It also covers structure types, the materials used, and the difference between deep litter and cage systems — all based on experience from farms across Uganda.

Quick Navigation

CHAPTER 1: TYPES OF POULTRY HOUSES

Well-designed layer house with proper ventilation and nesting areas

1. Layer Houses

Layer houses are designed with specific needs in mind, as these birds are kept for egg production. One of the key factors in layer house design is space. While many farmers measure space in square meters—often allowing 1 square meter per 6 birds—our approach is to use square feet for more precise planning. We allocate 1.5 square feet per layer bird, ensuring more accurate space usage, especially in situations where exact measurements don't fit neatly into meters. This approach helps avoid confusion when dealing with fractions of meters.

Layer houses tend to be larger than broiler houses because layers stay for a longer time and need nesting areas. A key difference between layer and indigenous bird structures is the inclusion of laying nests. These laying nests are placed outside the main space of the house, allowing eggs to roll out after being laid. This design saves space inside and makes egg collection easier, reducing the need to enter the house and disturb the birds.

Ventilation is crucial for layers since these houses can become congested with birds staying for many months. For storied layer houses, each floor is given a height of 8 feet to ensure proper airflow. Even for ground-level structures, the height remains at 8 feet, with a roof elevation of about 3 to 6 feet above that. This ensures the house stays cool and fresh, keeping the birds healthy and productive.

Proper spacing and airflow reduce stress, improve egg quality, and help maintain consistent production.

Modern broiler house with automated feeding systems

2. Broiler Houses

Broiler houses are built with a focus on raising birds quickly for meat, usually within 5-8 weeks. We recommend about 1 square feet per broiler, slightly more than standard practice which is 1.3 square feet, to allow them space to move and reduce stress.

One critical detail is the floor. Because broilers produce a lot of manure, we ensure the floor is carefully leveled and often raise it with a thick layer of cement. This makes it easier to scoop out waste, keeping the ground firm and clean. Ventilation is another top priority, as broilers consume a lot of water and create heat. We often design these houses with a height of 8 feet, sometimes even 9 feet, to allow for maximum airflow. Large open sides with roll-up curtains help adjust the ventilation as needed.

Another unique aspect is the brooding area. Since broilers need warmth during their early days, and have shorter cycles of 5-8 weeks, we design a separate brooder within or adjacent to the main house. This ensures the farmer can provide the necessary heat and care without disturbing the older broilers and also reduces the stress of always preparing the brooder for the new flock.

Overall, broiler houses are simple, functional, and designed to support fast growth, with strong floors, ample ventilation, and easy access for feeding and cleaning.

Simplicity and hygiene are key — feeders and drinkers should be evenly spaced, and lighting must be adequate for feeding at night.

3. Indigenous / Kuroiler Houses

Indigenous poultry structures share many similarities with layer houses, especially in terms of space requirements. We also measure around 1.5 square feet per bird, similar to layers, ensuring that these birds have enough room to move, forage, and thrive.

One key difference is that the laying nests are placed inside the structure. Indigenous birds often have a strong natural instinct to brood and hatch their own eggs, or farmers collect these eggs for incubation. By keeping the nests inside, the eggs remain safe and free from tiny cracks that can occur when they roll out. This ensures better hatch rates and healthier chicks.

Another important feature of indigenous houses is the inclusion of multiple perches. These birds love to perch and roost, so we add several sturdy perches at different heights inside the house. This not only keeps them happy and reduces stress, but also makes the most of vertical space within the house.

Ventilation remains crucial, as indigenous birds are hardy but still need fresh air. The height of these houses is similar to layers, around 8 feet, allowing for good airflow even with perches and nesting boxes inside.

These structures promote natural behavior, reduce stress, and encourage better mothering for farmers who hatch chicks locally.

CHAPTER 2: STRUCTURAL TYPES

Multi-level storied structure

Traditional ground structure

1. Storied Structures

Storied poultry structures are a smart solution for farmers who are limited on land, especially in urban or residential areas. By building vertically, farmers can keep more birds in the same footprint, making efficient use of space.

When constructing storied houses, we often use timber for the floors and beams, but it's crucial that these timbers are strong and durable. We recommend timbers at least 8 inches in diameter to act as columns and beams, ensuring they can support the weight of multiple levels. Each floor is built with a height of around 8 feet to provide enough ventilation and space for the birds and the farmer to move around easily.

In storied structures, the floor design also needs to allow for waste removal and good drainage. We often use wire mesh, wood off-cuts and the mixture sand and cement, making cleaning easier. The top floors need to be well sealed and stable to prevent any accidents or stress to the birds.

Storied designs are particularly popular for layers and sometimes indigenous birds, though they can also be used for broilers with careful planning. The key benefit is that storied structures let farmers maximize their flock size without needing more land.

Many farmers mistakenly believe storied structures save money by reducing the number of iron sheets needed, but that's not entirely true. The savings on roofing are often offset by the cost of casting strong floors for each level. We recommend using offcuts, which are affordable and strong, combined with a layer of mortar made from sand, cement, and an expanded mesh to hold it all together. This creates a strong, stable surface that can bear the weight of birds, equipment, and people.

Because of the complexity and risk of accidents—such as structural collapse—these houses should always be built by a specialist or someone who has experience with multi-level poultry structures. We strongly advise farmers not to attempt building storied houses on their own if they are unsure, as safety is paramount.

⚠️ Important Note: Storied houses do not always save money. While you may use fewer roofing sheets, the cost of strong flooring and supports can be high. Always involve an experienced structural builder to prevent collapse and ensure safety.

2. Ground Structures

Ground structures are an excellent choice for farmers with large pieces of land, as well as those in windy areas where a lower profile helps reduce wind resistance. Ground structures are also recommended for new farmers and those with limited budgets. If you're just starting out, for example with 500 birds, a ground structure is a cost-effective and practical way to begin.

While ground structures are simpler and cheaper to build, that doesn't mean they should be taken lightly. Even though they're on the ground, strong winds can still damage them, especially the roof. So it's important to use high-quality timber and make sure the structure is sturdy. Also, consider the direction of the sun and wind when positioning the house. This ensures the birds stay comfortable and the structure lasts longer.

Overall, ground structures are a great option for farmers who have the space and want a simple, reliable structure, without the complexity and cost of storied houses.

Ground houses remain the best choice for beginners and for large commercial farms on rural plots.

CHAPTER 3: MATERIALS FOR POULTRY STRUCTURES

Quality materials ensure durable and safe poultry housing

The primary materials we recommend for poultry houses are iron sheets and timber. For roofing, silver-coated or galvanized iron sheets are excellent, especially in Africa where heat is a challenge. These sheets reflect sunlight, keeping the house cooler, and they're affordable and easy to find. For the frame, eucalyptus timber is highly recommended. It's strong, grows straight, and is readily available, making construction easier and more durable.

For flooring, we emphasize the importance of a solid base. While concrete is unnecessary for ground structures, compacting the soil and casting a simple layer of sand and cement can go a long way in keeping the house clean and stable. For storied structures, offcuts and mortar make strong floors that can handle heavy loads.

Mesh is another essential material. Chicken mesh and wire mesh protects the birds from predators like cats and dogs and prevents wild birds from entering and spreading diseases. These meshes come in different types depending on the region, but they are crucial for keeping the flock safe.

All these materials work together to create a durable, functional poultry house. By balancing cost and effectiveness, farmers can build structures that protect their birds and maximize productivity.

These materials strike a balance between affordability, durability, and comfort — key to any successful poultry venture.

CHAPTER 4: DEEP LITTER VS. CAGE SYSTEMS

Deep litter system with wood shavings

Modern cage system for layers

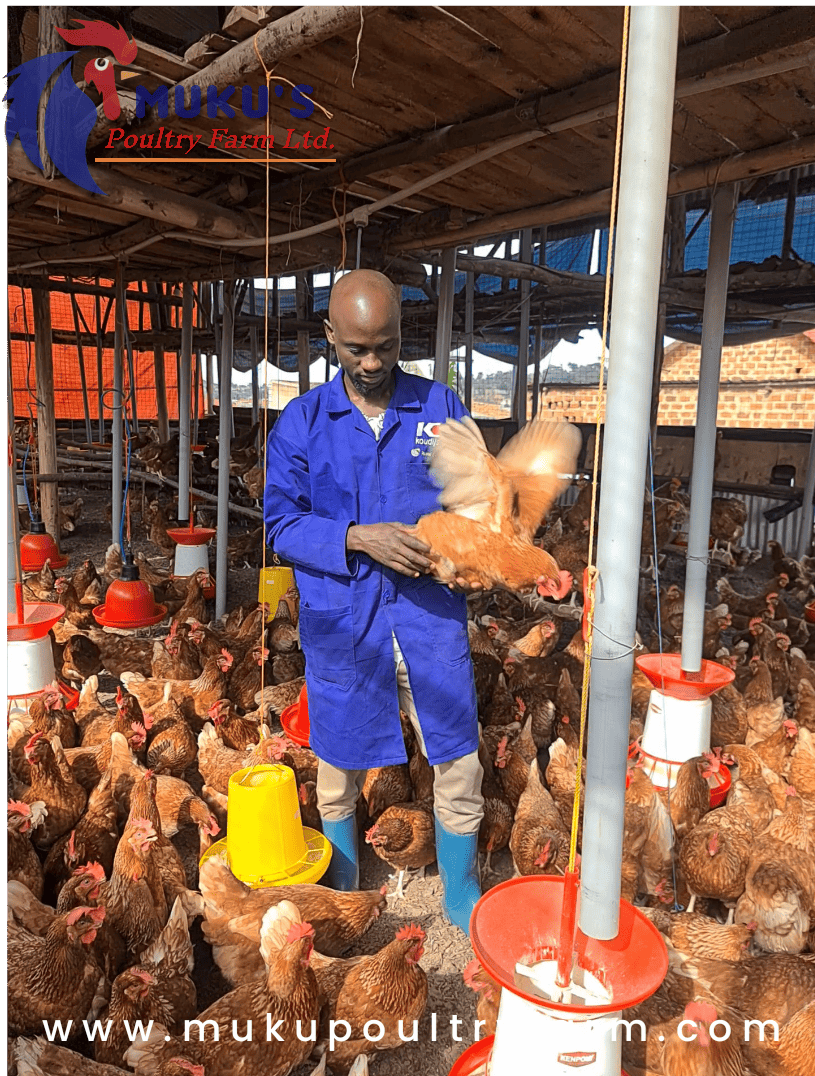

Deep litter is the most popular system in Uganda for good reason. It's simple, affordable, and doesn't require specialized skills to manage. However, it does require attention to detail. You need a well-ventilated structure, and the litter—whether it's wood shavings, coffee husks, or similar—should be at least 5 inches deep. This helps absorb moisture, reduces odors, and can stay in place for months without needing to be replaced if managed well.

Cage systems, on the other hand, require significant investment upfront. You need funds for both the structure and the cages. Daily manure removal can be labor-intensive, and without proper management, the smell can become a problem. Unless the cages are fully automated, you still have to feed and collect eggs manually, which reduces the advantage over deep litter.

Cages can be beneficial if fully automated, but even then, animal welfare is a concern. Birds in cages often experience more stress due to limited movement. We're not discouraging cages entirely, but deep litter is often more economical and better for the birds' well-being.

1. Deep Litter System

The deep litter system is the most widely used method in Uganda. Birds live freely on a thick layer of absorbent material.

With proper care, one litter batch can last 4–12 months, saving costs.

2. Cage System

The cage system confines birds in compartments, common for commercial layer farms.

Unless fully automated, cage systems can be demanding for small-scale farmers. Deep litter remains the better starting point for most Ugandan farms.

Conclusion

Knowledge is the first foundation of a strong farm. Before hiring builders or buying materials, every farmer should understand how poultry houses function and how design affects bird health and profitability.

This guide has covered the major types, materials, and systems to help you make informed choices. With this knowledge, you can supervise construction confidently and avoid costly mistakes.

At Muku's Poultry Farm Ltd, our mission is to ensure farmers succeed with quality structures, expert guidance, and durable materials. Visit our website or contact our team to see sample designs and learn how we can help you build a poultry house that lasts.

The Eight Core Secrets for a Successful Poultry Farm

By Muku's Poultry Farm Ltd – "Starting with us, succeeding with us."

I. Introduction

Poultry farming remains one of the most promising agribusiness ventures in Uganda and across the world. With population growth and rapid urbanization fueling the demand for chicken meat and eggs, both new and established farmers have a golden opportunity to prosper.

Beyond its profitability, poultry farming also brings immense nutritional value — supplying families with affordable, high-quality protein through eggs and meat. In addition, poultry manure enriches the soil, supporting sustainable agriculture for crops and gardens.

At Muku's Poultry Farm Ltd, we've seen that one of the major challenges in Uganda's poultry sector is the lack of professional guidance. Many farmers fall victim to poor advice, weak structures, and unqualified service providers.

That's why we're committed to providing premium, professional services — backed by quality testing, expert supervision, and trusted recommendations. Our goal is to build a strong community of informed farmers who thrive together.

With Muku, you're not just farming — you're building a sustainable future in poultry.

THE 8 CORE SECRETS FOR A SUCCESSFUL POULTRY FARM

Whether you're just starting out or already running a farm, these eight principles are the foundation of lasting success. Think of them as the building blocks of your poultry house — without them, the structure becomes shaky. But when you master them, your farm stands strong and profitable.

Let's dive into the secrets every serious poultry farmer should know.

Success starts with passion and dedication

1. PASSION — The Fuel That Keeps Your Farm Alive

At Muku's Poultry Farm, we've learned that passion is the lifeblood of every successful farmer. Poultry farming demands dedication — from gathering information and building structures to managing feeding, lighting, and health.

Challenges will come, especially in the beginning, but passion is what keeps you going when things get tough. Treat your farm as a full-time commitment, not a side hustle. Birds require consistency — and so does success.

A good example is a farmer who started with just 200 layers after the COVID-19 pandemic and has since grown to over 2,000 birds — all driven by passion, discipline, and patience.

Your passion must also extend to your workers. Hire people who love what they do — those who treat the birds as their own and care deeply about the farm's wellbeing. Shared passion creates shared success.

2. RESEARCH — Know Before You Grow

Many farmers jump into poultry farming without adequate research — and that's the first step toward failure. Research helps you understand your abilities, budget, and goals before you even buy your first chick.

Through proper research, you'll learn:

Research also prevents financial stress. Instead of over-borrowing or starting too big, you'll know how many birds you can manage comfortably.

How to research effectively:

Always cross-check what you learn — not all advice online or from fellow farmers is reliable. Verified knowledge is the backbone of a successful farm.

Choose locations with good accessibility and expansion potential

3. SELECTING A FARM LOCATION — Where Success Begins

Your farm's location can make or break your business. Here's what to consider:

4. GETTING A PROFESSIONAL SITE ENGINEER OR SUPERVISOR

Your poultry structure is the heart of your farm — it determines bird comfort, productivity, and health. Poor design can lead to serious problems like bad ventilation, disease outbreaks, and water leakages.

Always hire a professional site engineer or consultant to design and supervise construction. At Muku, we've adopted innovative yet affordable building techniques that combine durability with practicality, preventing common issues like overheating or poor drainage.

If you choose your own builder, bring in a qualified consultant to monitor progress. This small investment will save you from huge losses in the long run.

Pro tip: Never compromise on structure quality — your birds will live there every day. Build once, build right.

5. SOURCING QUALIFIED SUPPLIERS

Finding reliable suppliers for chicks, feed, and vaccines can be challenging. Unfortunately, some sellers offer substandard products that lead to poor performance or disease outbreaks.

To protect your farm:

At Muku's Poultry Farm Ltd, we work with trusted suppliers and can recommend or directly provide high-quality chicks, feeds, and equipment. Working with reliable partners keeps your farm consistent and profitable.

Regular veterinary care prevents disease outbreaks

6. ACQUIRING AND BEFRIENDING PROFESSIONAL VETS

Your veterinarian is your farm's doctor — and your best defense against losses. But not every vet is qualified. Some use farms as testing grounds for unverified herbal treatments or experimental methods.

Choose a dedicated and professional vet who values your farm's success over quick money. Here's how to identify one:

Building a strong relationship with your vet ensures faster response to emergencies and better long-term flock health.

7. RECRUITING EXPERIENCED WORKERS

Your workers are the hands of your farm. Hiring unskilled labor might look cheaper, but it often costs more in mistakes and losses.

Always prioritize experienced and responsible workers. If you hire beginners, ensure you have at least one trained worker or the knowledge to supervise properly.

Smart hiring tips:

Experienced workers handle birds with care, follow routines accurately, and notice early signs of disease — saving you time and money.

8. BASIC FARM KNOWLEDGE — Be the Farmer Who Knows

Even if you're the owner, you must understand the basics. That knowledge helps you supervise workers, train new ones, and make smart decisions.

🐣 Handling Day-Old Chicks

Always buy chicks from reputable hatcheries — avoid village-based operations. Some hatch eggs from medicated hens, producing weak or diseased chicks.

Choose companies with strong reputations and proper breeding standards. Healthy chicks are the foundation of your farm — never compromise.

Proper Ventilation

Good air circulation is essential for bird health. Here are key points to follow:

Ventilation prevents heat stress, ammonia buildup, and respiratory diseases — ensuring your birds stay active and productive.

Well-managed farms lead to sustainable success

Conclusion

Running a poultry farm isn't about luck — it's about knowledge, planning, and passion. When you combine these eight secrets, you set a foundation that's strong enough to withstand challenges and smart enough to grow profitably.

At Muku's Poultry Farm Ltd, we're dedicated to guiding farmers with tested knowledge, quality services, and trusted products. Whether you're starting small or scaling big, our goal is to help you succeed — every step of the way.

Your Learning Progress

Poultry Structures

Farm Management

Poultry Health

Learning Resources

Join Our Learning Community

Meet Our Founder

Mukomeza Denis

Our mission at Muku's Poultry Farm is not just to sell products, but to empower Ugandan farmers with knowledge and resources. Every farmer's success is our success. We believe that through proper education, quality inputs, and dedicated support, we can transform poultry farming into a sustainable and profitable venture for all.

Contact Denis directly: +256-704-508647 | Email: denis@mukuspoultryfarm.ug